High-Specific Surface Area Calcium Hydroxide

Technical Specifications of High-Specific Surface Area Calcium Hydroxide

Ca(OH)₂ Content (%): ≥90%

Moisture Content (%):<2

Particle Size (325 mesh):≥85%

Surface Area (m²/g):>45

Pore Volume (cm³/g):>0.2

CAS No. 1305-62-0

Category:Environmental Protection

Introduction

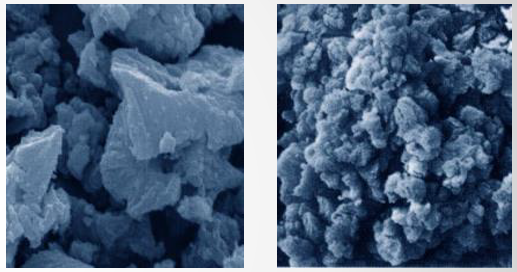

Introduction to High-Specific Surface Area Calcium Hydroxide

High-specific surface area calcium hydroxide, with the chemical formula Ca(OH)₂, is a highly efficient and versatile material widely used in flue gas treatment and environmental protection. With a focus on innovation and sustainability, our company specializes in the research, development, and production of advanced calcium-based desulfurizers. Our high-specific surface area calcium hydroxide is engineered to deliver superior performance in reducing harmful emissions, making it a preferred choice for industries such as steel, power generation, and waste incineration.

Key Features of High-Specific Surface Area Calcium Hydroxide

- High Purity: ≥90% Ca(OH)₂ content, ensuring effective and reliable performance.

- Enhanced Surface Area: >45 m²/g, providing superior reactivity and efficiency.

- Low Moisture Content: <2% wet content, ensuring stability and ease of handling.

- Eco-Friendly: Complies with global environmental standards, including REACH certification.

- Cost-Effective: Reduces operational costs by optimizing desulfurization efficiency.

How High-Specific Surface Area Calcium Hydroxide Works

Our high-specific surface area calcium hydroxide is designed to maximize reactivity and efficiency in flue gas treatment. Here’s how it works:

Neutralization of Acidic Gases

Calcium hydroxide reacts with acidic pollutants such as sulfur dioxide (SO₂), hydrogen chloride (HCl), and hydrogen fluoride (HF) to form neutral compounds, effectively reducing air pollution.

Example Reaction:

Ca(OH)₂ + SO₂ → CaSO₃ + H₂O

Enhanced Reactivity

The high surface area (>45 m²/g) and pore volume (>0.2 cm³/g) ensure rapid and complete reactions, even at low temperatures.

Improved Air Quality

By removing harmful gases, our calcium hydroxide helps industries comply with stringent environmental regulations and improve air quality.

Advantages of Using High-Specific Surface Area Calcium Hydroxide

- High Efficiency: Removes up to 99% of acidic gases, ensuring compliance with emission standards.

- Easy to Handle: Available in powder form with low moisture content (<2%), making it easy to store and transport.

- Sustainable: Reduces the environmental impact of industrial emissions.

- Cost Savings: Lowers the need for expensive air pollution control equipment.

Applications in Flue Gas Treatment

- Steel Industry: Used in ironmaking, steelmaking, and rolling processes to control emissions.

- Power Plants: Reduces sulfur dioxide emissions from coal-fired power plants.

- Waste Incineration: Neutralizes harmful gases from waste-to-energy plants.

- Chemical Manufacturing: Minimizes emissions from chemical processes.

Technical Specifications

| Parameter | Standard Product | Our Product |

|---|---|---|

| Color | White powder | White powder |

| Ca(OH)₂ Content (%) | ≥85 | ≥90 |

| Moisture Content (%) | 2 | <2 |

| Particle Size (325 mesh) | ≥85% | ≥85% |

| Bulk Density (g/ml) | 0.4-0.65 | 0.4-0.65 |

| Surface Area (m²/g) | ≥40 | >45 |

| Pore Volume (cm³/g) | – | >0.2 |

Why Choose Our High-Specific Surface Area Calcium Hydroxide?

As a leading Calcium Hydroxide Manufacturer, we are committed to delivering high-quality products and tailored solutions to meet your specific needs. Here’s why our calcium hydroxide stands out:

Proven Expertise

With years of experience in flue gas treatment, we have successfully implemented our calcium-based desulfurizers in major enterprises such as Baowu Steel, earning consistent praise from clients.

Customizable Solutions

We offer tailored purity, particle size, and packaging to suit your flue gas treatment requirements.

Global Standards

Our products comply with international standards, including REACH, ISO, and MSDS, ensuring safety and reliability.

Expert Support

Our team of over 20 engineers, including 5 experts with more than 10 years of experience, provides comprehensive support from design to implementation.

Frequently Asked Questions (FAQ)

Q1: How effective is high-specific surface area calcium hydroxide in reducing SO₂ emissions?

A: Our calcium hydroxide can remove up to 99% of sulfur dioxide from flue gases, making it highly effective for air pollution control.

Q2: Is high-specific surface area calcium hydroxide safe to use in industrial settings?

A: Yes, it is safe when handled according to MSDS guidelines. Proper protective equipment should be worn during use.

Q3: Can high-specific surface area calcium hydroxide be customized for specific applications?

A: Absolutely. We offer customized purity, particle size, and packaging to meet your requirements.

Conclusion

High-specific surface area calcium hydroxide is a proven and reliable solution for flue gas treatment, offering high efficiency, cost savings, and environmental benefits. Whether you’re managing emissions from steel plants, power plants, or waste incineration facilities, our high-purity calcium hydroxide ensures compliance with environmental regulations and improves air quality.

As a trusted Calcium Hydroxide Manufacturer, we are dedicated to providing innovative and sustainable solutions for industries worldwide. Partner with us to meet your flue gas treatment needs and contribute to a cleaner, greener future.

Contact us today to learn more about how our high-specific surface area calcium hydroxide can benefit your operations!